As per customers respective rolling requirements, based on our tens of years’ rolls manufacturing and global marketing experiences, we’re able to supply China prime rolls for your metal rolling mills. Our rolls manufacturing plants occupy an area of 130,000 square meters with annual production capacity of various types of rolls about 40,000 tons.

Main rolls manufacturing facilities

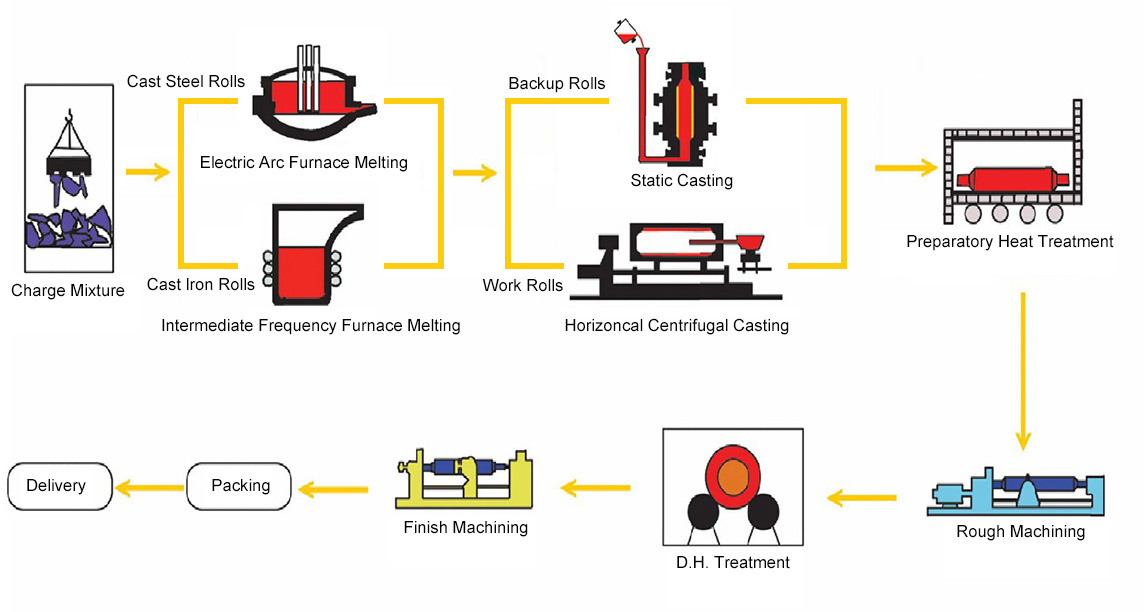

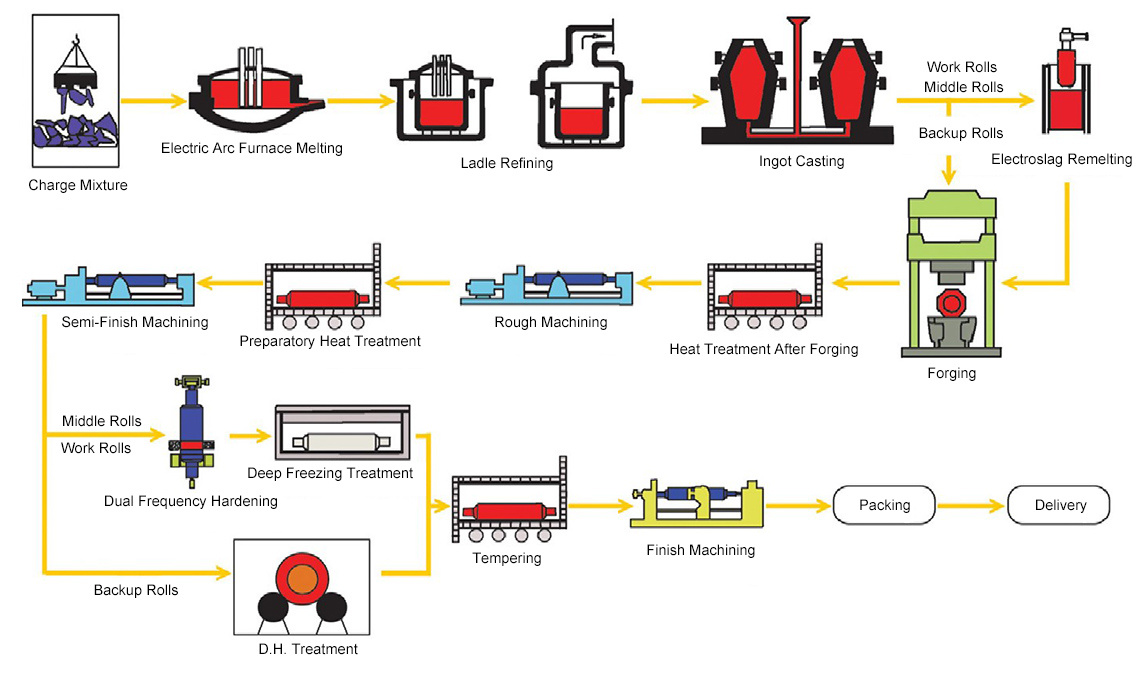

1. Melting equipment

Medium frequency induction furnaces: 1.5/3.0/5.0/12/20 ton

EAF: 30 ton, LF-VD: 45/70 ton, ESR furnaces: 10/15 ton

The melting equipment are PLC automatic-controlled and environmentally-friendly, equipped with dedusting facilities.

Raw materials are purchased from selected long-term supply sources. The melting process witnesses accurate composition control along with refining process.

2-1. Casting equipment

Horizontal centrifugal casting machines

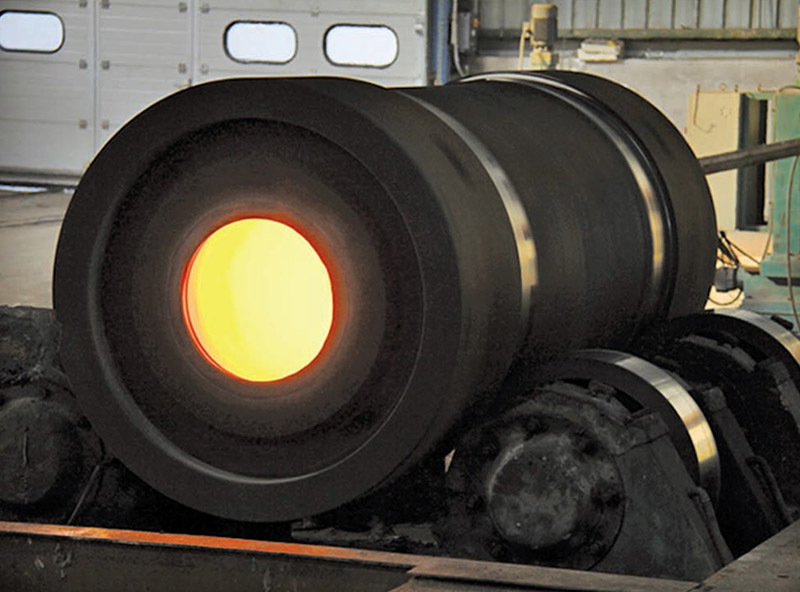

2-2. Forging equipment

One set of 45MN Oil Press is equipped to guarantee forging ratio and deformation amount for forged steel rolls.

3. Heat treatment equipment

High/Medium/Low temperature bogie-hearth resistance furnaces, D.H. heat treatment furnace, Duel-frequency quenching machine, Spray quenching machine etc. All furnaces are computer-controlled.

Small non-uniformity of furnace temperatures assures rolls uniform hardness.

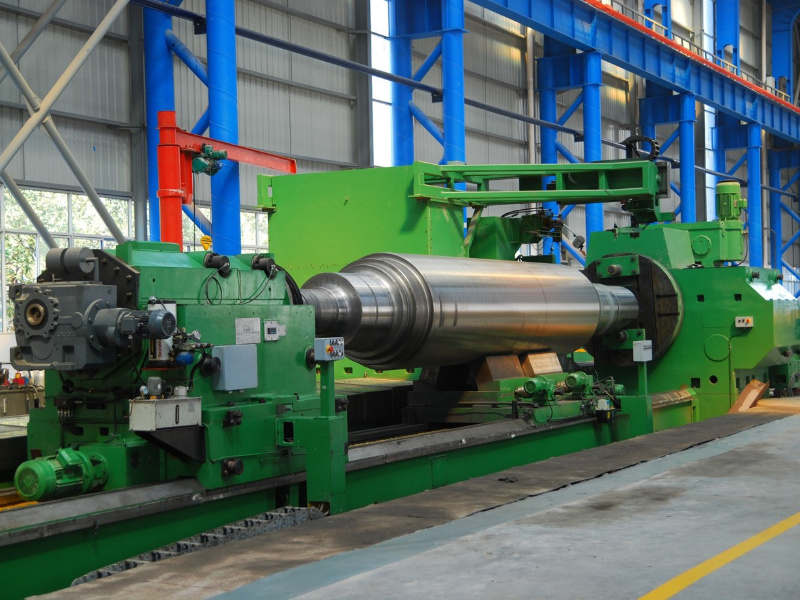

4. Machining equipment

Horizontal CNC Lathe, CNC Grinder, CNC external Grinder, Gantry Milling machine, Two-side Milling Machine, Floor-type Boring & Milling Machine, Vertical Lathe, Roll No. Marking machine etc., to meet various rolls production requirements with high precision and special machining requirements.

5. Testing equipment

Direct-reading spectrometer, IR C/S Analyzer, Microstructure microscope, Desk-type microscope, Hardness testers, Digital ultrasonic tester, Tensile testing machine etc.

Our rolls manufacturing plants are ISO certified plants. Superior testing equipment and comprehensive quality assurance system guarantee each roll well meet customers’ rolling requirements.

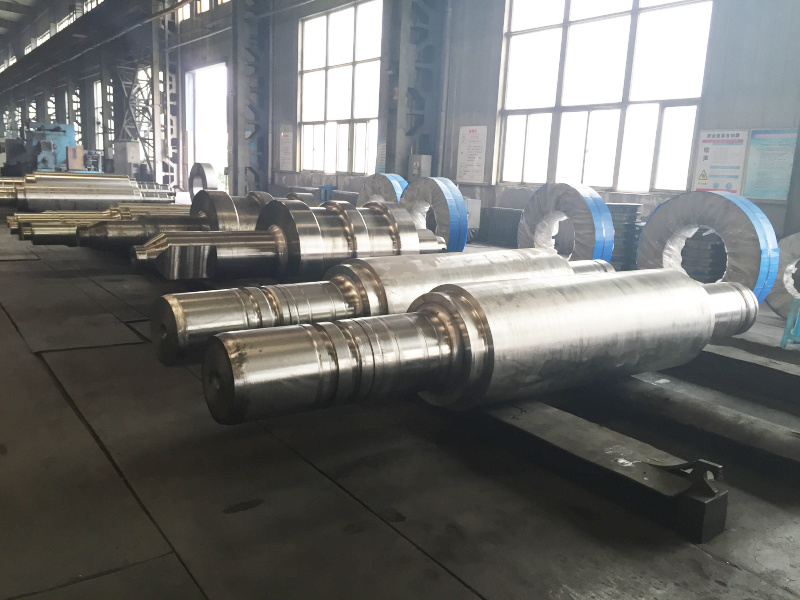

6. Finished Rolls

7. Packaging

8. Shipping